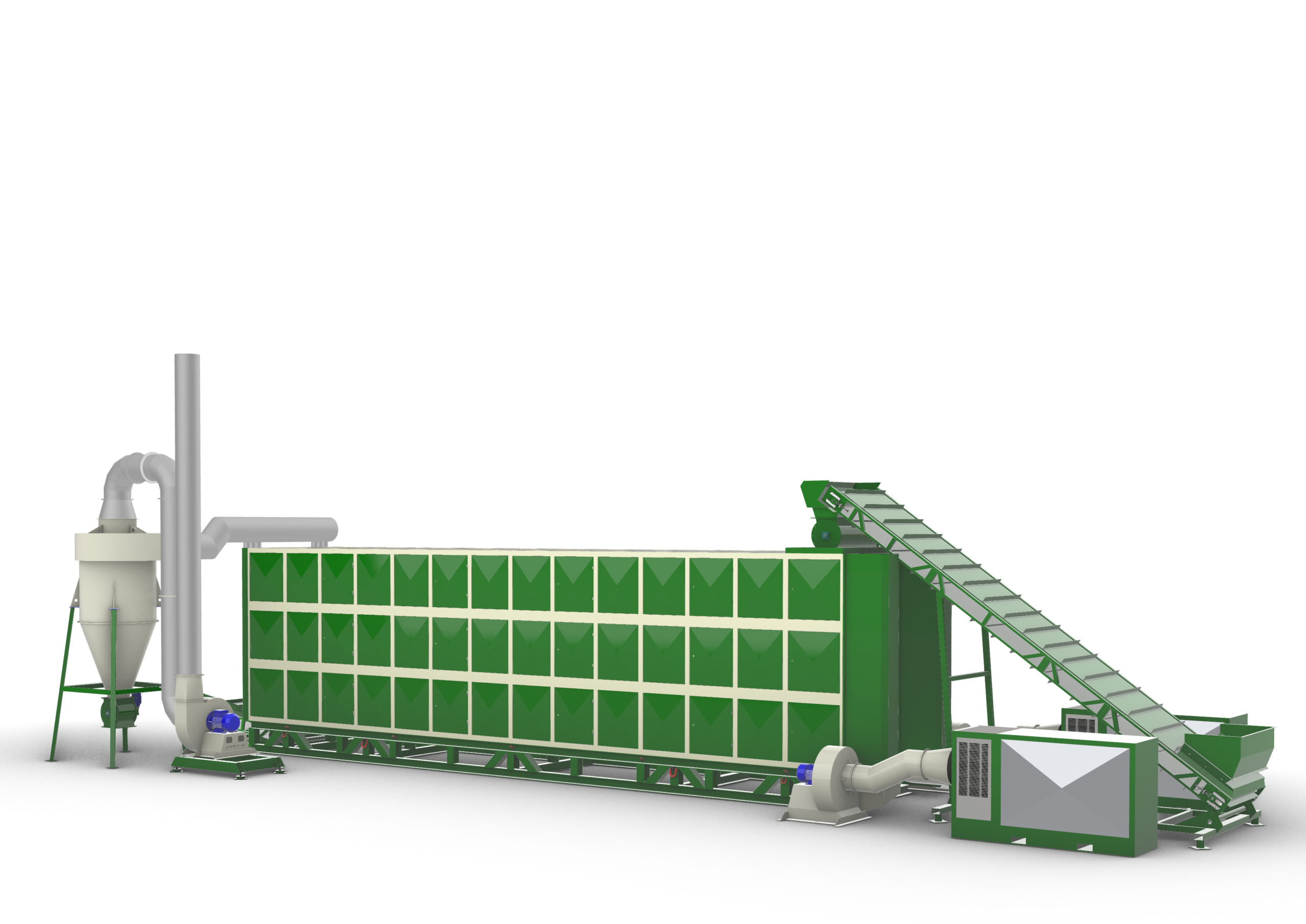

Belt Dryer (hemp-cannabis, straw, cereals)

Belt dryer BD12

Belt dryer is designed and designated for gentle drying of agro commodities such are hops, hemp, cereals and suchlike material of vegetable origin. It works on the principle of forcing in hot air into the enclosed drying box which is divided into three drying zones. In the box, material is advanced on three teflon belts and constantly dried to the required output moisture with the help of hot air inlet throughout the whole process of drying. Output moisture of used material can be regulated by means of input temperature value (30-150°C) as well as by speed setting of drying belts. Heated air is led into the drying box by two transport fans by means of distributive pipeline into the individual zones and through diffusor nozzles on the drying material along the entire length of the drying belts. Air flow in the zones is regulated by closing plates by which it is possible to regulate differential pressure in individual zones. Air pressure which is led on the material can be also regulated by these closing plates. Moist air and fine particles are sucked out of the system by discharge fan through solid particles separator when the air is led out of the system and fine particles are separated from the air by means of rotary valve. Both types of fans i.e. transport and discharge fan, are regulated by frequency converters by which airflow volume in the drying box can be set. The system is equipped by sensors in order to control and regulate input temperature and temperature on the drying belts of individual zones. The motion of belts is monitored by sensors and in the case of belt deviation out of the roller, the belt is then automatically leveled by actuator for belt alignment. Input and output of material are ensured by belt conveyor and enclosed rotary dispenser. Finished dried material is discharged also by belt conveyor. In order to ensure heat for the whole drying system it is possible to use gas, diesel or oil aggregate with the power of 500-600 kW, electric heater with the power of 2 x 90kW.

Belt dryer system consists of

- Heat source – 2x heater, diesel fuel, light fuel oil, gas

- Transport fan – 2x fan of 7,5kW

- Feeding conveyor – belt conveyor with hopper

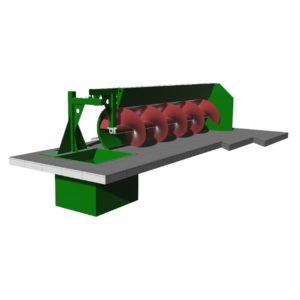

- Rotary dispenser – material dispenser on the belt, tourniquet

- Drying box – enclosed heat insulated drying box with three belts, pipeline designated for distribution and circulation of drying air

- Discharge fan – transport fan of 15kW

- Centrifugal separator, cyclone – solid particle separator

- Rotary valve – rotary separator, tourniquet

- Exhaust pipeline – pipeline designated for air exhaust

- Discharge conveyor – belt conveyor for discharge of finished dried material

- Electrical switchboard with control system

All parts and components are made of material in a high quality according to European and American standards.

Sophisticated belt dryer system

- Inlet temperature control in the range of 20-140 ° C

- Control of airflow and air pressure in the drying box individually for each belt

- Control and automatic maintenance of set temperatures in the drying box

- Automatic tensioning and keeping of drying belts on rollers against movement

- Setting the drying process to automatic mode

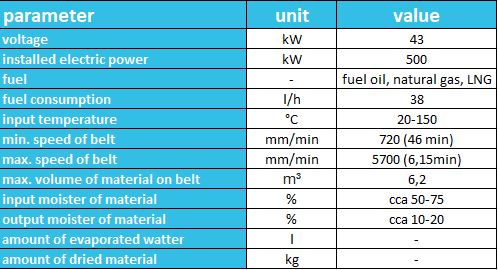

Technical data of belt dryer

Description of the process of drying and regulation

The drying process of agro material such is hop, hemp, cereals and other commodities of vegetable origin is dependent on input moisture, size and fraction of material, required output moisture and acceptable admissible input temperature. The run of the whole system is control by central electric switchboard which is equipped PLC control unit that works with transferred data from sensores and thermocouples and in connection to these data adjust the automatic run of the whole system in the way to reach the required parameters during the drying process. The process of drying and thus the quantity of finished dried material can be regulated in two following ways.

Continuous drying

Continuous drying is performed in the way that the material is continuously dosed on the drying belt (in the layer of about 15 – 20cm) and material is advanced by constant adjustable speed throughout the whole process of drying. Hot air is led on material through the diffusor nozzles along the entire length all three belts by means of transport fans. Temperature of drying air can be regulated between 20-150°C depending on required temperature. The motion of material on the belts in the drying box can be set on required speed depending on needed length of stay of the material for drying in the box.

Cyclical drying

Cyclical drying is performer in the way that the material is dosed on the drying belts in set up quantity (in the layer of about 15 – 20cm) so that all three drying belts are filled in a uniform layer. Then the belts are stopped for the required time and hot air is led on the material by transport fans. After set up of certain of drying, the belts are set in run again and finished dried material is discharged out from the drying box on the discharge conveyor. The control system allows to set any variant of the drying cycle in any period interval i.e. it is possible to set period of belt motion as well as the belt pause interval depending on output moisture.